Sensing Modalities & Network

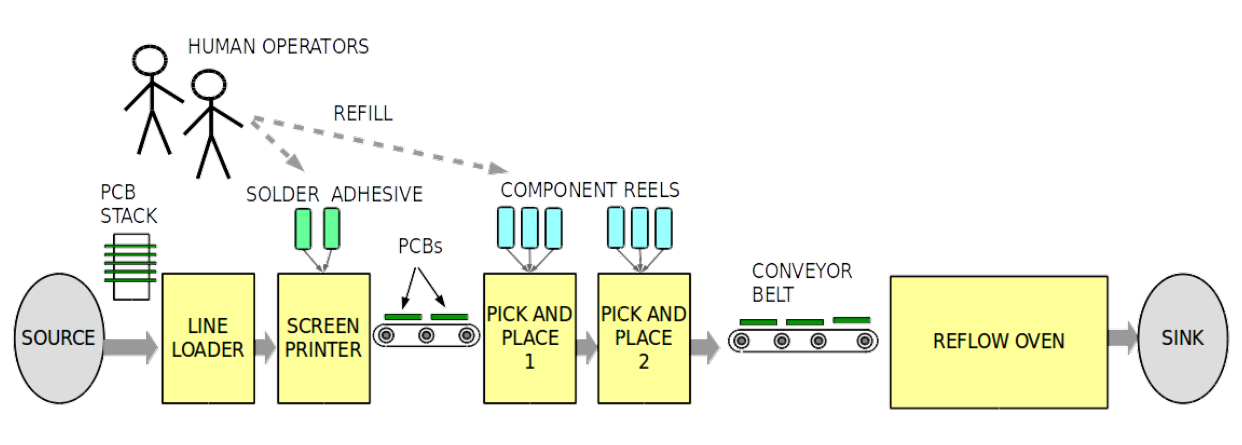

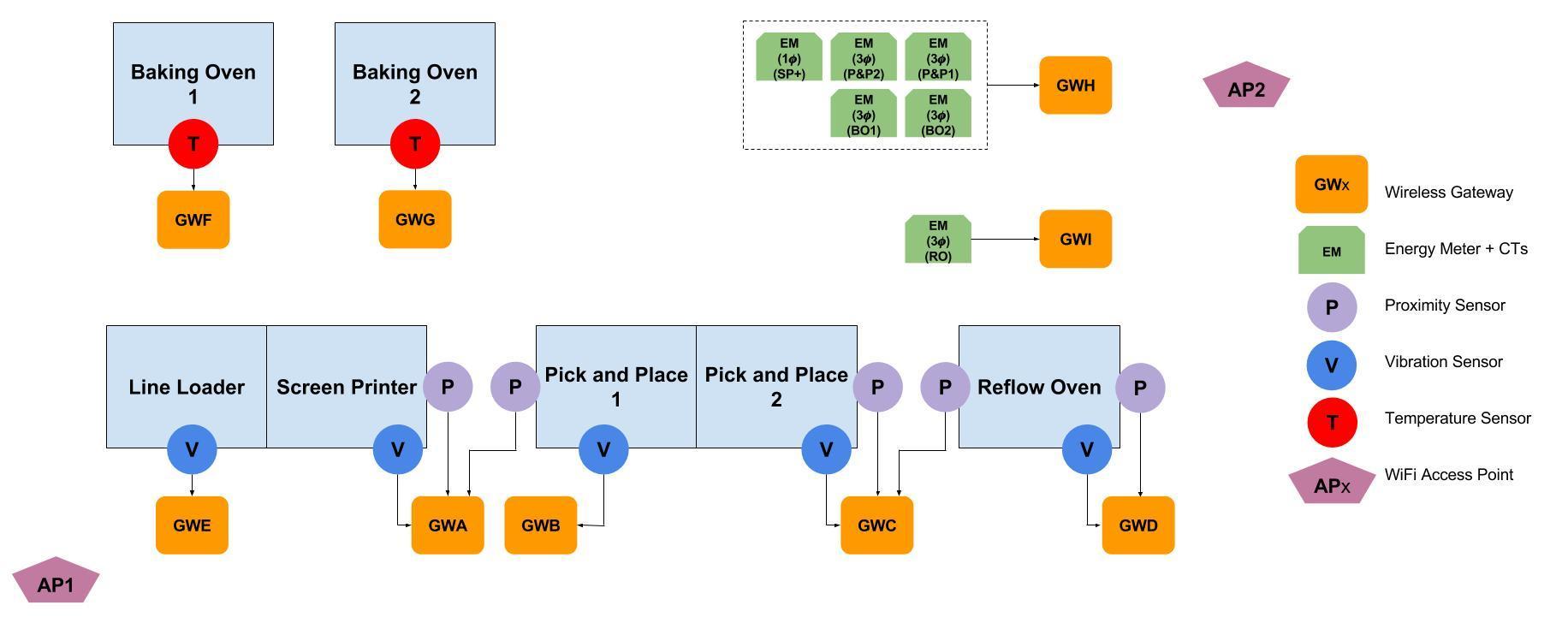

Various sensors such as vibration, proximity, temperature sensors and current meters were placed along the automated assembly line as shown in Fig. 1.

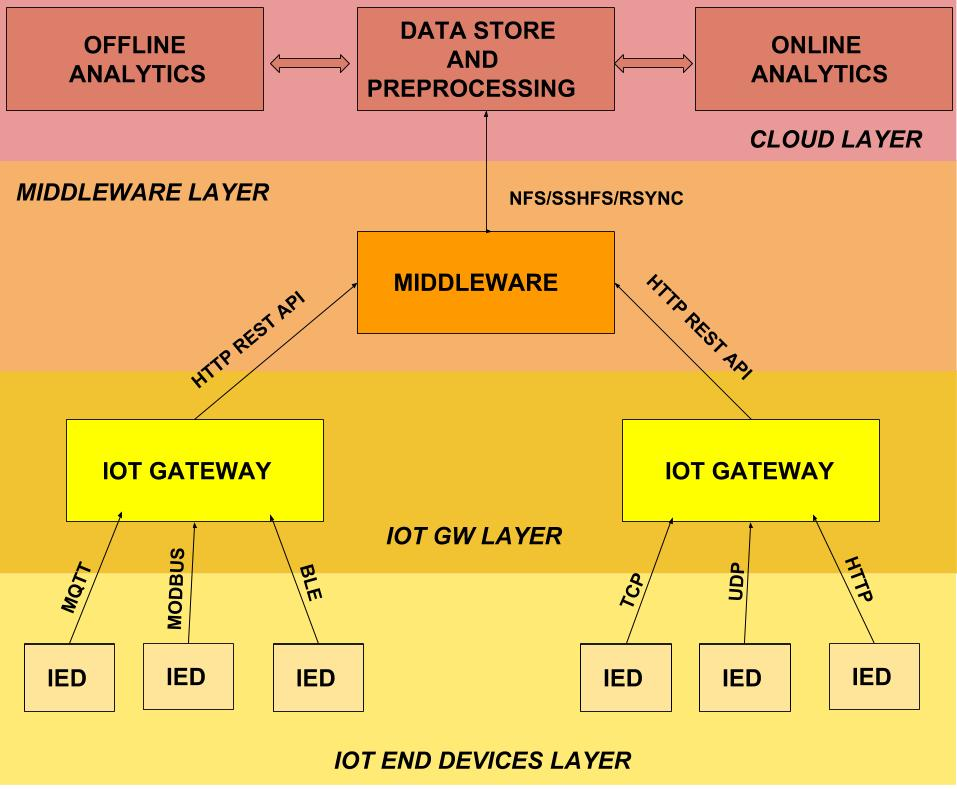

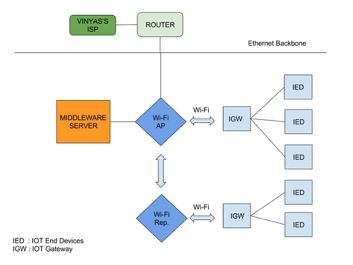

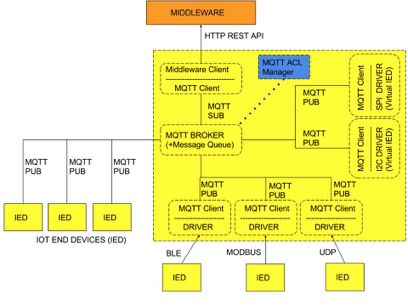

Data Flow Architecture - Data flows from sensors connected to IOT End-Devices at the factory via IOT Gateway and Middleware server to the data store server at RBCCPS, IISc Bangalore, as shown in Fig. 2. The IOT Gateways receive sensor data over GPIO, MODBUS and BLE and use MQTT service internally before forwarding them over REST APIs to the Middleware server which hosts an Elasticsearch database. The data is time stamped at the IOT Gateways and the clocks of the gateways are synchronised using NTP service with the NTP server running on the Middleware. The communication network architecture is shown in Fig. 3 which consists of two wireless access points creating a subnet to which the IOT gateways and Middleware connect to. The architecture of microservices of the IOT gateway is in Fig. 4.

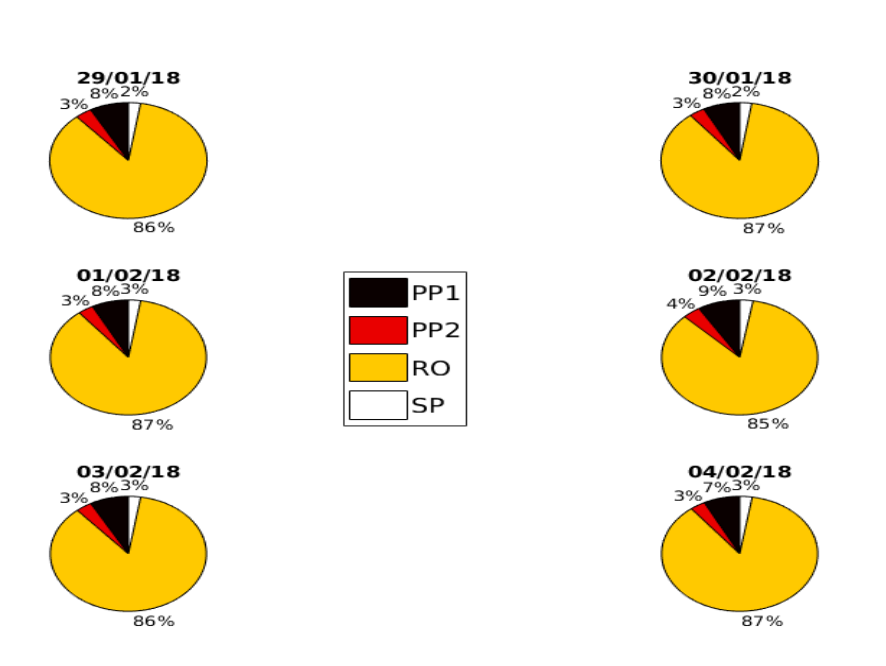

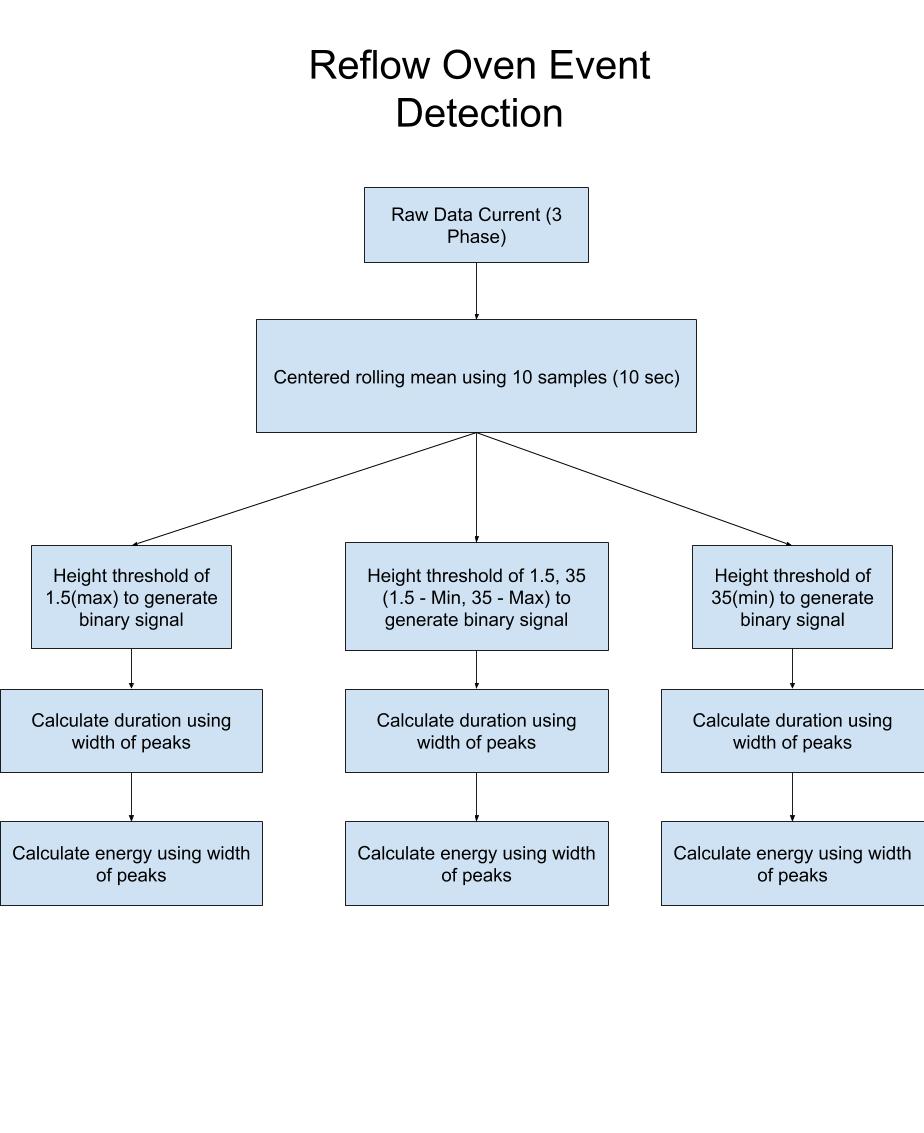

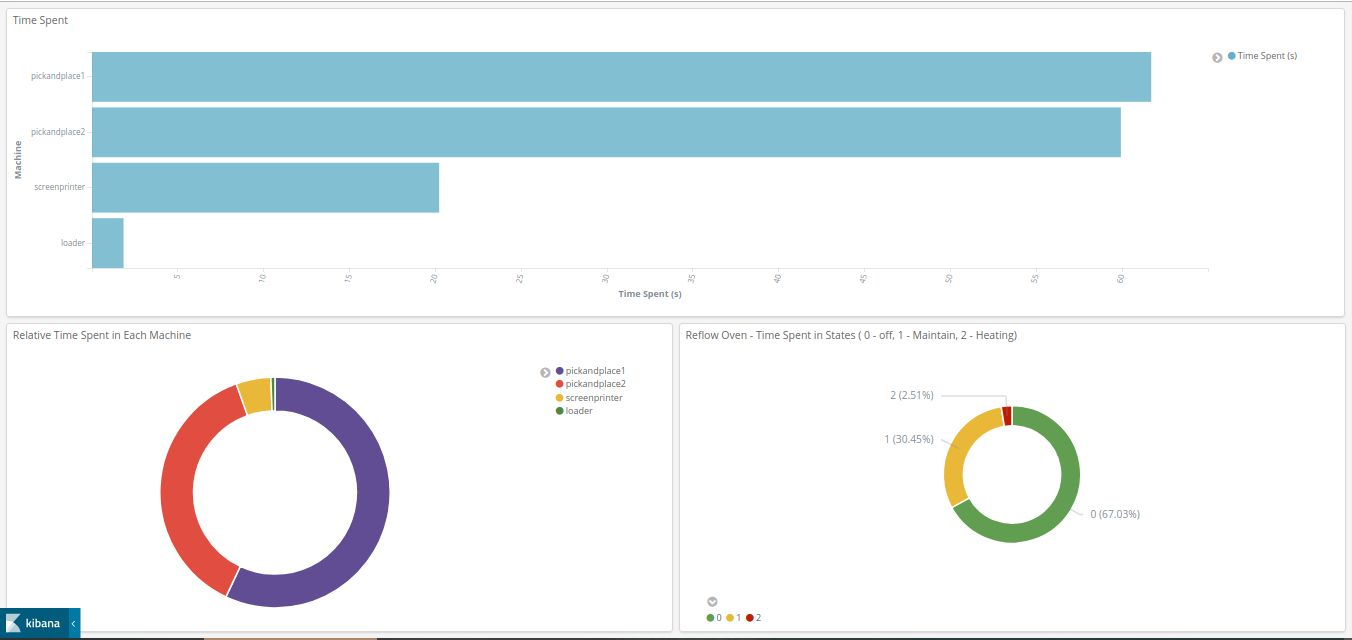

The Middleware at Vinyas and a cloud compute server are connected over a VPN for transparent accessibility of the elasticsearch database. The cloud server is leveraged to perform event detection and state estimation algorithms on the incoming data every 15 minutes. Kibana, a visualization service, runs at both the middleware and the compute server for inspection of the incoming raw data, detected events and the estimated states.